The plant was built to the north of the pre-existing lime and brick plant, on the site of the worked-out brickfield. Notice the four chimneys to the left of the railway tracks this is the Cement Works. I would like to know what the house is in front of the Cement Works.

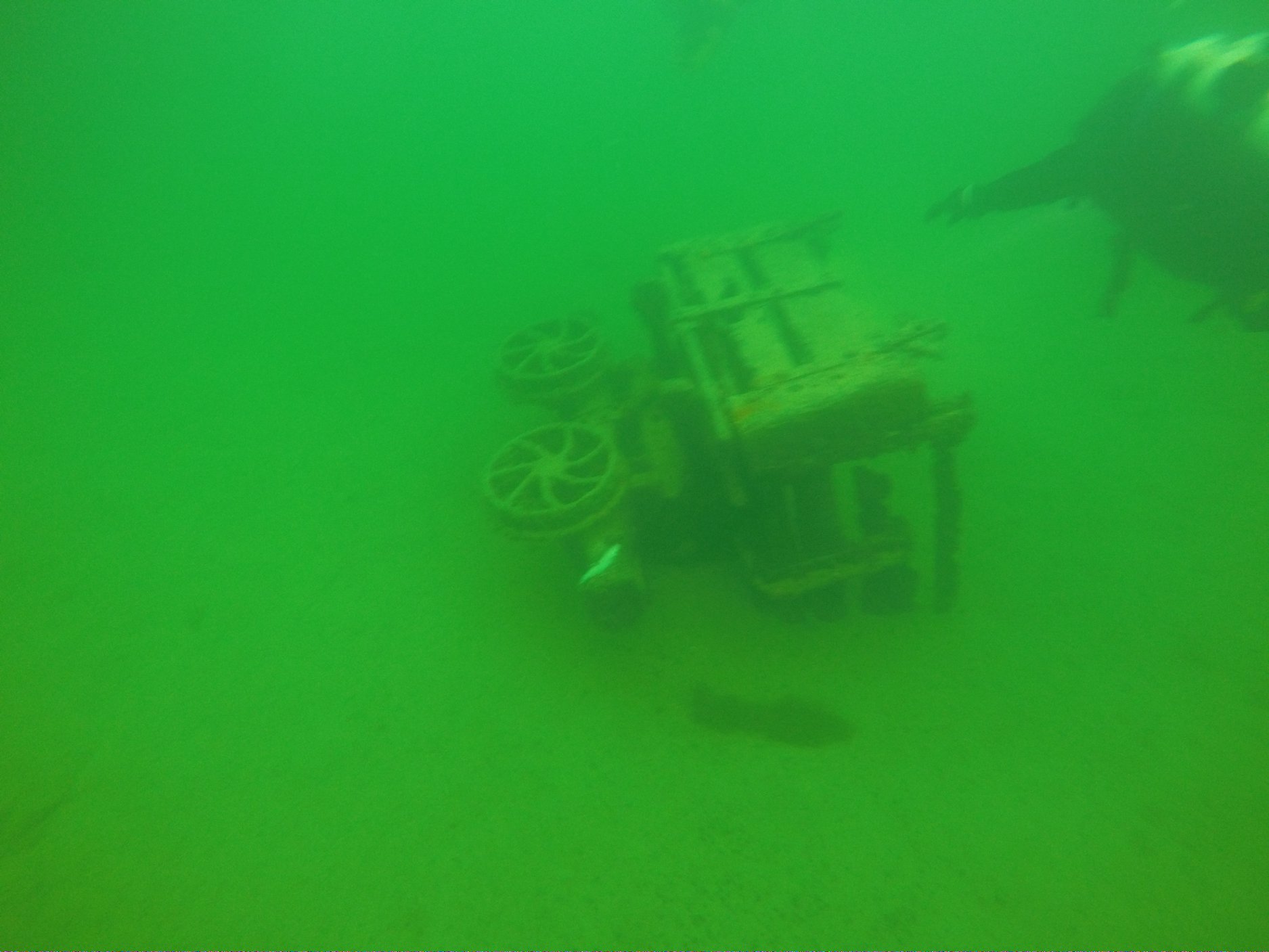

A dive Francesa Iosue did in March 2019 in the Blue Lagoon.

She is a member of BSAC North Herts Divers based in Stevenage.

They own the dive rights to the Blue Lagoon.

Frankie took some fantastic pictures and allowed me to use them.

These are the old quarry buggies submerged in about 8 meters of water. Great visability which you don’t get often there! Water was pretty chilly, around 6 degrees in the deepest part of the lake at 12 meters. We also gave the resident cat fish some cat food 😆 – but i didn’t get any footage of him sadly.

Portland cement manufacture had been attempted at the site before the plant described was launched. These “costly and fruitless attempts” involved burning the un-blended chalk marl, and when the new plant started, chalk and gault clay were used. The clay was already available from the much more substantial brickworks next door.

Blue Lagoon before it filled with water. Notice the pump which was needed to keep it dry

My wife at the blue lagoon 1977.Notice the crane jib (35 years ago)she was expecting our son Paul. It was in fact not a crane but a steam excavator, sometimes called a steam navvy. It was made by Ruston Proctor in 1909 and had the serial number 306.

FRANCESA IOSUE the diver in the Blue Lagoon

In 1977 Ray Hooley and his team salvaged the excavator from the lagoon and it was taken to Lincolnshire for restoration work. It was later donated to The Vintage Excavator Trust at Threlkeld in Cumbria. It is supposed to be the only surviving model of it’s type.

The plant started up with a set of six Johnson chamber kilns, capacity 120 tons/week. In 1887 four locally-designed double-deck chamber kilns were installed, giving 100 tons/week. the total capacity 940 tons/week. The installation of the rotary kilns involved the removal of the first block of chamber kilns in 1912. The remaining static kilns continued in commission, although only intermittently used: they were last operated in 1926. All transportation was by road and the Great Northern Railway. Most of the site is long cleared, and is now partly occupied by a readymix plant, but the second chamber kiln block still remains. Some foundations are still visible on the unoccupied ground towards the railway. The quarries are now flooded.

Blue Lagoon in the 50’s ex neighbour Rocky Rogers don’t know the others

Portland cement is one of many materials that can be made by making a finely-ground mixture of limestone and clay, and burning the mixture at over 1000°C. The properties of the product obtained differ widely depending on the composition of the mixture and the temperature of burning.

The original “invention” or “discovery” of Portland cement sets the standard for all subsequent cement industry history, in that it cocooned in a web of disinformation, misunderstanding and lies. In this work, the term Portland cement is applied only in the modern sense. “Portland cement as we know it” can be simply defined as a calcareous cement containing (intentionally!) significant amounts of alite (“tricalcium silicate”).

Cement Burner Greatgrandad big Jim Allen.

The consensus of opinion is that this product was not a “true” Portland cement first made in 1842. They took great pains to hide the details of the process from espionage, and even from their own employees. They invented an elaborate and fictitious track record for this product.

Because of the “smoke and mirrors” surrounding the early product, and the lack in those days of any legal requirement to describe a product correctly, it is often difficult to determine when firms first made “true” Portland cement. Early entrants into the industry were fooled by the prevailing disinformation into thinking that Portland cement must be fairly easy to make (and this mistake is still made today!), and they ended up with over-simplified processes making products that were at best of marginal quality, and often did not meet the true definition of the product at all.

Maria ,my late sister, Alma , my mum ,late Aunty Emilia , and Clive Lombari

However, at this time, even heavy industrial construction was still dominated by brick masonry, and earlier types of cement were already well-established in this market.

England remained the main source of the World’s cement during the 1850s and 1860s. This export market allowed the English plants to expand production and mature their technology, and the home market for the product began to take off from 1860 onward, rapidly overtaking that of the earlier products. Exports all around the globe remained a major part of the industry’s business until the 1890s, when it suddenly became apparent that foreigners and colonials could make Portland cement as well.

The factories of Arlesey had many children working long hours. Dr Barnardo along with friends such as Earl of Shaftsbury and Lord Cairns became responsible for some of the Acts that were put before Parliament to save the lives of children and give them a better life along with giving them an education, such as the Factories Act providing for child and female labour to be regulated. According to a press report that day 10,000 children went back to school’. This was a big labour loss for the owners. It must have badly affected Arlesey Cement and Lime Company. Not to mention the poor families that relied on the childrens wages Adult workers left their jobs on a farm and went to work in the Cement works, their wages shot up overnight.

Three Counties Asylum (Fairfield Hospital)

The clay works directly behind Fairfield Hospital was dug by hand and is triangular in shape covering some 3 acres in total. The northern end has a shear chalk cliff dropping away to a maximum depth of about 10mtr and is the deepest part of the old clay works. The eastern side is the shallowest at around 3.5Mtr deep, the western side is a little deeper at 4Mtr. . The chalk that had been dug out by hand was then transported down the hill by gravity on narrow gauge tramway to the cement lime and brick works on the Hitchin road of Arlesey. A steam excavator was then purchased.

The green lagoon continued to be one source of clay till about 1901 when the clay works was abandoned and the works moved to what is known today as the Blue Lagoon which was nearer the brick-works. Records show that in 1903 1,500 tons of lime and cement was produced weekly. The chalk filled wagons were hauled up from the bottom of the quarry by a steel cable powered by a stationary steam engine. They were then let down to the works by gravity, a man rode down on the wagons and stopped them just before the Hitchin Road by spragging the wheels. A small steam engine then took them over the road and shunted them up an incline to empty them into the slurry pits. The empty wagons were then hauled back up to the pit by the cable.

My greatgrandad Big Jim Allen was down on the 1911 census as a Cement Burner.

If My great uncle Ranji Singji Allen was in a good mood he would let his daughter and her friend ride up to the Lagoon in the empty wagons after she had dropped his lunch off. They would then walk back home .The road crossing was controlled by a man who signalled to the winding house by a system of bells.

Ranji’s daughters Jean and Sheila Allen

In about 1925 the steam pump that was used to keep the pit dry was coming to the end of its working life and with the cost of a new diesel pump it was decided uneconomical to keep running which marked the end of these clay works in Arlesey, by 1930 the pit was closed and allowed to fill with water. Most of the working machinery was left where it stood including an old steam power excavator which had its jib protruding out of the water for many years until it was salvaged in 1977.The pumps in the quarry were stopped and the pits were filling with water in 1930 with the cement works finally closing in 1932.

Prior to the crane being removed the top of the jib had been used as a diving platform for all the people who spent their summer days swimming in the Blue Lagoon.

The Hitchin road used to be packed both sides of the Hitchin Road with cars until parking restrictions were put in place. Lots of local men and boys have been drowned over the years, but a tragedy of three children trapped in a car 28th July 2001 made the authorities sit up and take notice of the problem. A lot of noise was made at the time , but not much has happened since.

The Chalk and clay excavating team in 1920. photo courtsey of Ray Hooley. Ranji Singhji Allen was one of the last workers to leave the Cement works when it closed in the big recession of 1930. Other families shunned Ranji’s because he still had a job and his Asylum Road neighbours had been laid off. Of course by the time Ranji was laid off some of them had been taken on by London Brick Works.

Ranji Allen and wife Laura on his wedding day (pUNCH aLLEN’S SON)

Ranji Allen was out of work in the 30’s when the cement works closed , but he eventually got taken on by London Brick where my grandad Herbert was Foreman until the late 50’s

Cement burner then Brickyard Foreman Granddad Herbert Allen

Herbert had also been a cement burner as well after serving in the First World War. He probably helped his cousin Ranji get a job at the brickyard.

The economic growth of Arlesey during this time was significant. With the coming of the Great Northern Railway in 1852 and with it improved methods of distribution the subsequent growth of the brick and cement works was immense. Previous to that steam traction engines hauled the bricks and cement to where they were needed. Shefford just a few mile to the west had the benefit of a canal and where barges brought in ‘coals from Newcastle’ they took away ‘vegetables from Bedfordshire’.

The closed cement works was used as a Prisoner of War Camp for Italians in 1940 , but that is another of my stories.

Does anyone remember the Wallace family who lived in brickyard house. They were Frederick Harold,Mabel, Dorothy,Jack,Brenda and Margaret?

LikeLike

not me it was derelict when i was a kid

LikeLike

Do you know when it was nicknamed blue lagoon?

LikeLike

I will try and find out

LikeLike