Arlesey is a boggy swampy village due to the clay in the soil . This made it an ideal place to make bricks .There were lots of Brickworks in Arlesey.

The Great Northern Brick Company.Arlesey Cement and Lime Company Brickworks , (London B.C. and BJH Forders) and Eastwoods at Arlesey Lake.

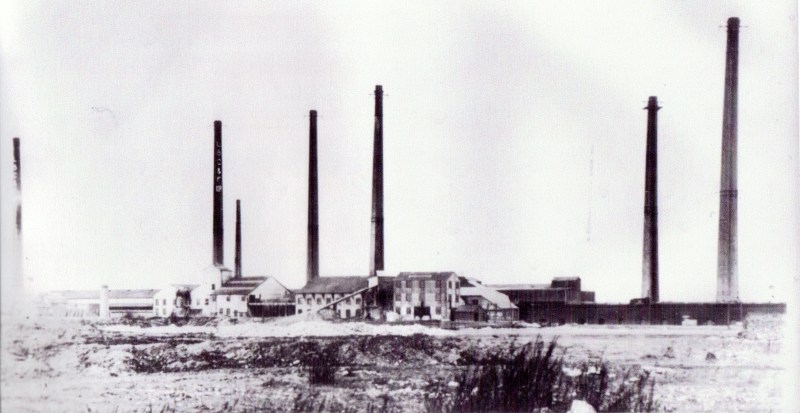

I am concentrating on tha largest .Arlesey brickworks was founded in 1852 by Mr Beart and he used the Gault clay from the Cretaceous Period to make Arlesey White bricks..

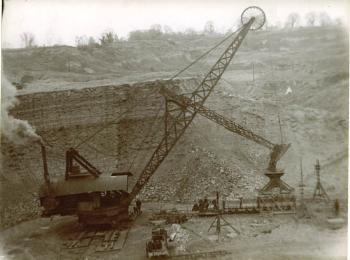

The clay was dug out of the Pit in a haphazard fashion , but when London Brick took over in 1929 science was used to dig in exactly the right places.

One weeks holiday with pay was only introduced in 1930 , by LBC. They believed in looking after their workers . The built a bowling green and bought a Social club with Snooker and Billiards facillities . They provided houses for the manager and foremen as well . During the World War II LBC did make weapons .After the War Arlesey brickworks no longer made normal bricks but only hollow bricks such as used in floors ceilings and partition walls and drainage pipes .

Out of the 32 London Brick sites this was the only one which made these patented products.

There is more to making bricks than meets the eye. It is no so much nowdays that straw is needed in the production of bricks but Chemists to control the very delicate build process.

It is not simply a matter of digging up the clay , moulding the bricks , then firing them. These bricks would not last very long at all. Each process is precise as a scientific experiment.

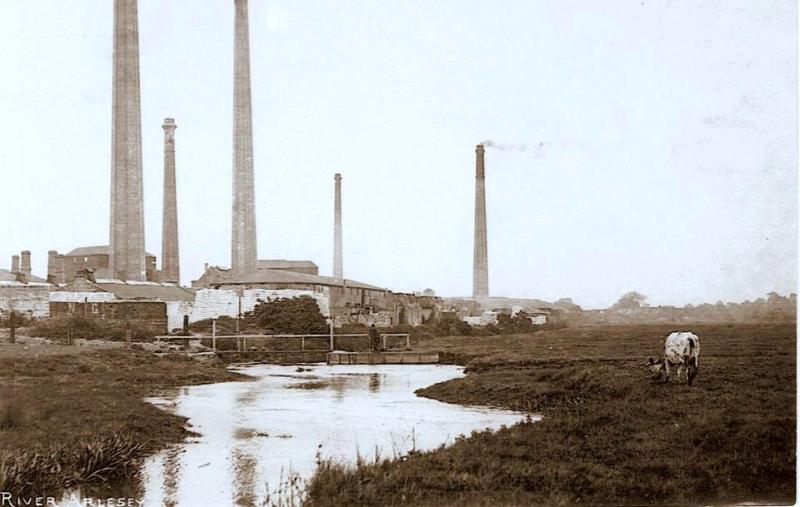

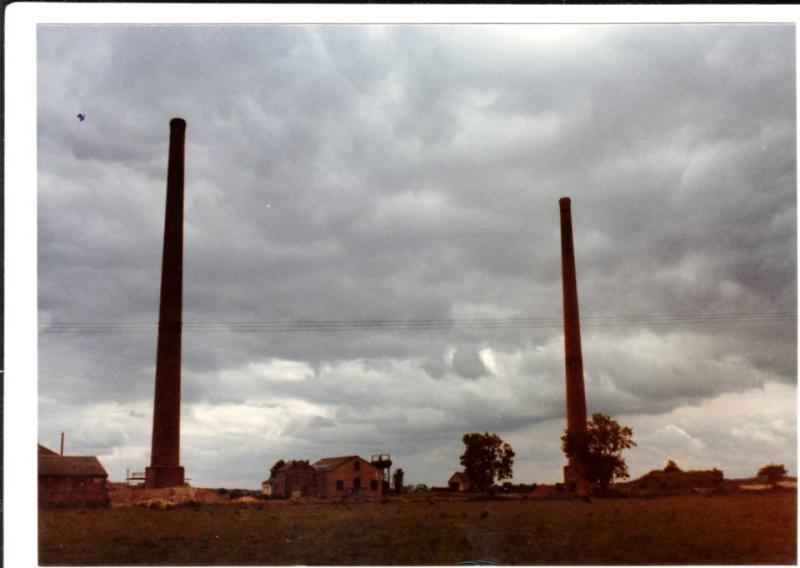

The chimneys were 230feet high and the base of the square chimneys is 15 feet. These are connected to the kilns and provide the tremendous draught needed for perfect combustion , and cooling . Fans could be used but would be much more expensive to run..

London Brick Company was taken over by Hansons who still own it now. I believe it is for sale. Hanson’s also own Butterley Bricks and Shanks and McEwan Lanfill. In the 80’s Butterly bricks started remaking Arlesey Whites. Butterleys is an Old Mining Company was based in Derby. In 1992 the last Butterley Brick was made at the Arlesey plant. Hanson Lanfill is still operating there today.Anybody know where the houses below are?

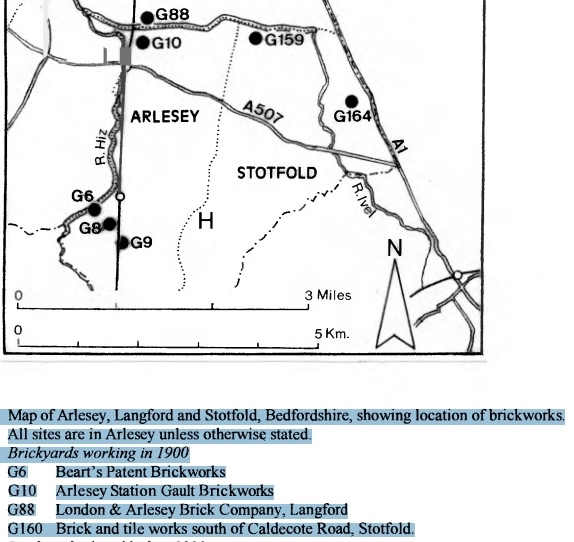

Map of Arlesey, Langford and Stotfold, Bedfordshire, showing location of brickworks.

All sites are in Arlesey unless otherwise stated.

Key: Brickyards working in 1900

G6 Beart’s Patent Brickworks

G10 Arlesey Station Gault Brickworks

G88 London & Arlesey Brick Company, Langford

G160 Brick and tile works south of Caldecote Road, Stotfold.

Brickyards closed before 1900

G8 Great Northern Brick Co. (incorporating G7 William Dennis’ Brickworks)

G9 Arlesey Brick and Lime Co. Ltd.

G159 Kiln at Astwick Road, Stotfold

Other

H Three Counties Hospital

BRICKMAKING AT ARLESEY, BEDFORDSHIRE, 1852-1932

The choice of bricks from Arlesey as the common bricks in the construction of the New War

Office between 1899 and 1906 should not come as a great surprise. The parish of Arlesey in the

south-east corner of Bedfordshire was a major brickmaking centre throughout the second half

of the nineteenth century (fig. 5). Buff/off-white Gault bricks were produced by various firms

in Arlesey from 1852 until about 1932; drainage pipes were still being made there when longstanding

BBS member Alan Cox compiled his Survey of Bedfordshire Brickmaking And there was a brief

attempt to resuscitate the making of Gault bricks at Arlesey between 1983 and the early 1990s.

When, in the early years of the twentieth century, the account of Arlesey was being

prepared for inclusion in the second volume of the Victoria County History of Bedfordshire,

three brickworks were recorded as operational: the Arlesey Brick Company, the Arlesey Station

Gault Brickworks and the London & Arlesey Brick Company. However, only the first was still

working when the volume was published in 1908 (see below and Tables 6 and 7).

The Arlesey Brick Company began in 1852, when Robert Beart (1801-1873) moved his

business interests some 20 miles south from his original base in Godmanchester, Hunts., a town

on the south side of the river Great Ouse from Huntingdon. Beart is sometimes described as ‘of

Huntingdon’ as he continued to live in Godmanchester, being its mayor six times. In

Godmanchester in the 1830s, he had established a business making bricks and, initially of much

greater significance, brickmaking machinery. A Beart machine was viewed by those members

who visited Marks Tey brickworks in July 2010. Beart’s patent still applied in 1865 when

Humphrey Chamberlain of Kempsey, Worcs., who had a patent for a new brickmaking machine,

stated that anyone who made perforated bricks with his machine was liable to pay a patent

royalty to Robert Beart.

The abundant Gault clay at Arlesey gave Robert Beart the opportunity to expand and to

build ‘an immense works’ beside the newly-opened Great Northern Railway line at Arlesey: the

railway from Leeds to London King’s Cross had opened two years earlier in 1850. A single

paragraph in the issue of The Builder for 18 December 1852 notes

Companies have been formed in the most eligible localities for the purpose of

manufacturing bricks in steam factories by a new patent process. One of these

establishments has for more than twelve months been in operation on a small scale at

Huntingdon where 6 men and 4 boys are making 60,000 bricks a week, no alterations of

weather in the slightest degree interfering with their operations. Under the same patent

and on an improved scale, immense works are just being put down at Arlesey, also on

the Great Northern line and a little more than 20 miles south [in the direction] of the

metropolis where about a million and a quarter [bricks] will be made for the London

market.

The next paragraph of this short notice gives some statistics for weekly production at other

brickworks using a steam engine and the patent process: Table 4 has been compiled from this.

It is not clear what time-frame is implied by the optimistic “about a million and a quarter

[bricks] for the London market”. Annual production of eight million bricks in 1858 would imply

a weekly production rate in the order of 160,000 bricks, which would be one of the highest

amongst firms then operating in England; but if the time frame for the expectation of a million

and a quarter bricks is monthly, production each week would be in the order of 320,000 bricks

(see Table 4).

Beart’s firm went through several changes of name. By 1877, the firm had become a

private company, Beart’s Patent Brick Co., and its clay pit had reached a depth of between 50

and 60 feet (between 15.25 and 18.3 metres). Kelly’s Directory of Bedfordshire in its 1885 issue

records that Beart’s Patent Brick Co. was in association with y had been producing off-white bricks from the Gault clay and

drainage pipes since October 1880 but as a brickmaker, the firm was short-lived, being taken

over by Beart’s in 1883; however, it continued as manufacturer of lime and cement. The clay

pit is shown as active on the Ordnance Survey map surveyed in 1880-81.

By the time the New War Office was being built, the firm had become a private limited

company, The Arlesey Brick Company (Beart’s) Limited; the name is first noted when the firm

was reorganised in 1898 and was the one it retained until the firm was taken over by the London

Brick Company in 1928. As previously noted, the first phase of brickmaking at Arlesey ceased

in about 1932. The Arlesey Brick Company (Beart’s) Ltd., is noted as a major brick producer in

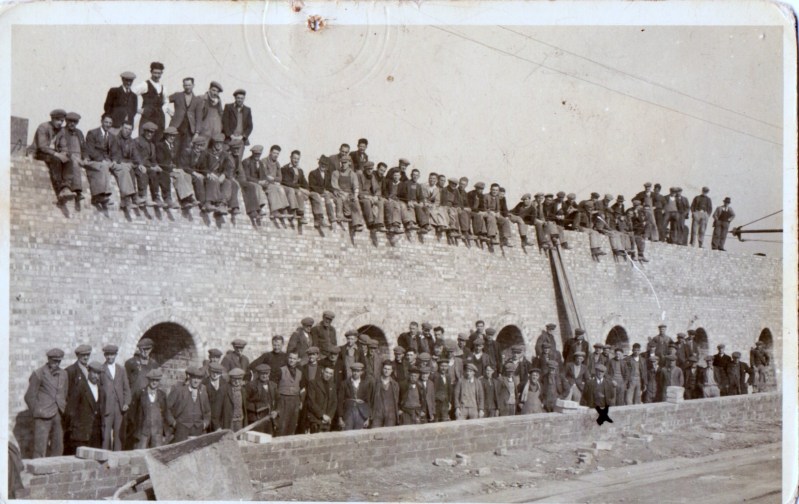

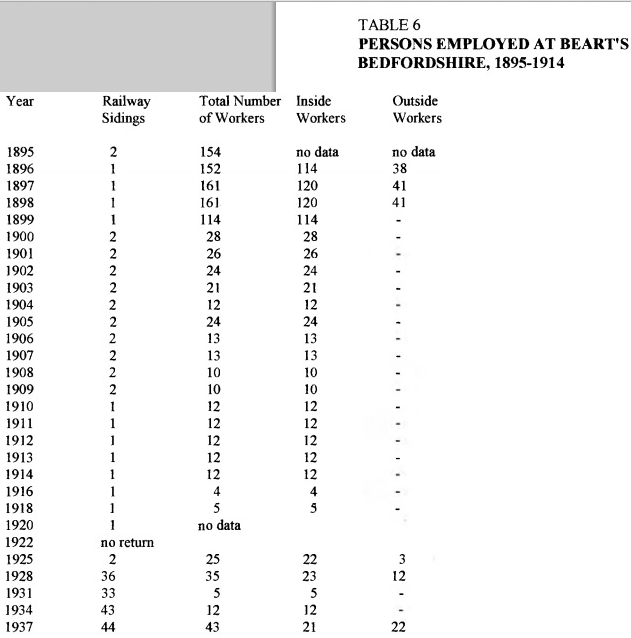

the Quarry Act Returns from 1895 to 1937. These give statistics of the number of employees at

each works where the clay pit had a depth of more than 20 feet (6.1 metres) and from which

Tables 6 and 7 are drawn. In 1895, Beart’s employed more men than any other brickmaking firm

in Bedfordshire: a total of 154 workers. However, from 1900, the number of employees drops

considerably (Table 6).

WEEKLY BRICKMAKING CAPACITY OF SELECTED BRICKWORKS

IN 1852

Beart works, Godmanchester 60,000 bricks

Beart works, Arlesey (projected) 1,250,000 bricks Time-frame uncertain

Beart works, Arlesey (possible) 320,000 bricks If projected production is per month

Beart works, Arlesey (actual in 1858) 160,000 bricks From return in Hunt, 1860

Cambridge 120,000 bricks

Rugby 120,000 bricks

Leicester 60,000 bricks

Liverpool 500,000 bricks

Manchester 600,000 bricks

Birmingham 600,000 bricks

Derby 120,000 bricks

Edward Gripper works, Mapperley

(near Nottingham)

360,000 bricks

Doncaster for Yorkshire towns 800,000 bricks

Source: The Builder, 10, 18 December 1852, page 800.

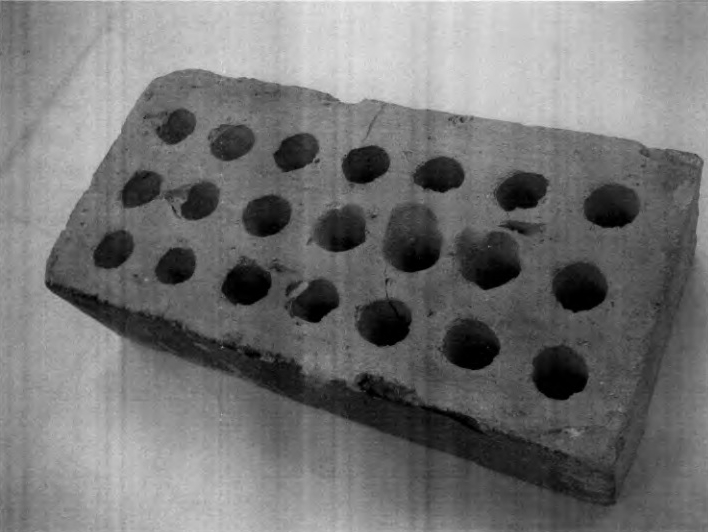

In 1852, Beart’s bricks at Godmanchester were perforated with twenty-four holes, in

three rows of eight’ those produced at Arlesey in the 1870s had only twenty-one holes, arranged

in three rows of seven (fig.7). The reason for the holes has been disputed. Modem wire-cut

bricks often have three large holes rather than a frog. These allow the fingers of the bricklayer

to hold the brick when setting it in mortar though that is not its primary purpose; and certainly

it cannot explain the much greater number of holes in a Beart’s patent brick. One explanation

given for the nineteenth-century practice is that the holes made the brick lighter and thus

provided an alternative to the frog. The Builder in June 1852 suggested that the holes allowed

the bricks to burn more thoroughly. Because of this, moisture could escape more easily and

without creating fissures. The brick produced with many small holes was supposedly very hard

and very strong, ideal, in fact, for load-bearing walls as in the New War Office which had to take

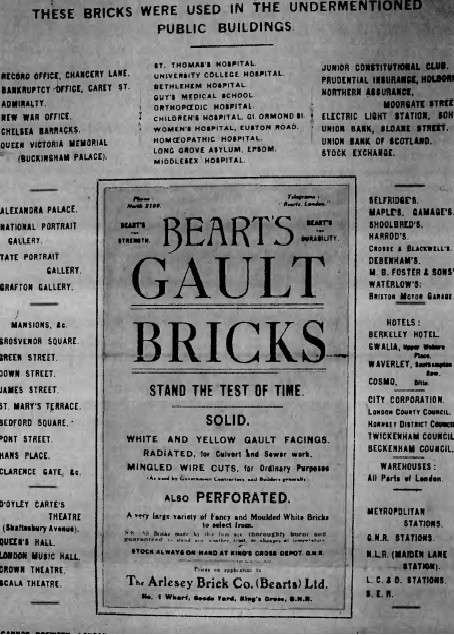

the weight of floors made of concrete slabs. As an advertisement (fig. 8) shows Beart’s also

made solid bricks.

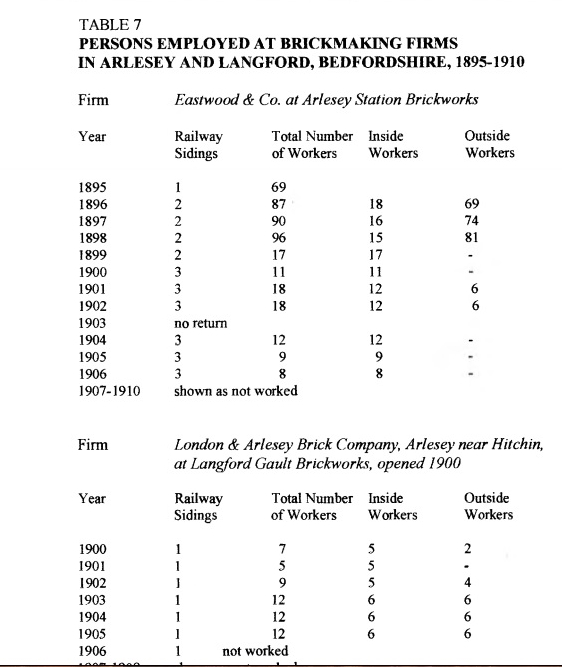

The two other firms operating at the very beginning of the twentieth century were both

completely separate from Beart’s. The Arlesey Station Gault Brickworks was opened in October

1882 by James McCullum Craig on land formerly part of Hermitage Farm, Arlesey; it was taken

over by a much larger firm, Eastwood & Co., in or before 1890. This brickworks was noted in

the Quarry Act Returns until 1910 but apparently had ceased operating by 1907, whereas in 1895

it had employed 96 workers (Table 7).

Just over the Cat Ditch, the parish boundary with Langford, was the works of the London

& Arlesey Brick Company. A brickworks was opened near Langfordhill Farm, adjacent to the

main Great Northern Railway line, in about 1900 but apparently had ceased working by 1906:

no return was submitted as required by the Quarry Act in that year or any other up to 1910, when

the record ceases (Table 7). Basically, production was uneconomic: the owners were unable

to produce bricks for less than their selling price.

Both the London & Arlesey Brick Company in Langford and the Arlesey Station Gault

Brickworks in Arlesey itself had railway sidings giving direct access to the main line of the Great Northern Railway

BRICKMAKING AT ARLESEY IN 1858

Arlesey

Brickworks

Gault Robert Beart Esq

Robert Beart & Co.

Bricks of various shapes to suit

architect’s designs:

8,000,000 bricks

Agricultural drain pipes:

1,500,000

Arlesey

Brickworks

Gault no freeholder.

Arlsey Brick Co.

[so spelled]

[included in the above]

Arlesey

Brickworks

Gault W.Dennis

William Dennis

Bricks and drain tiles

[no production figure given]

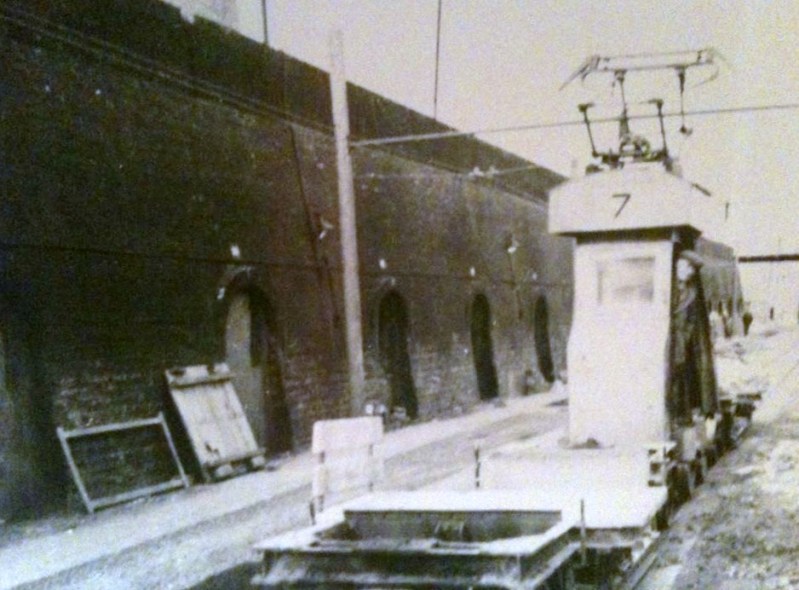

The London & Arlesey Brick Company’s siding was 16 chains (322 m) north

of Arlesey level crossing; that of the Arlesey Station Gault Brickworks was 93/4 chains (196 m)

north of Arlesey level crossing. Beart’ s Patent Brickworks had access to the main railway line

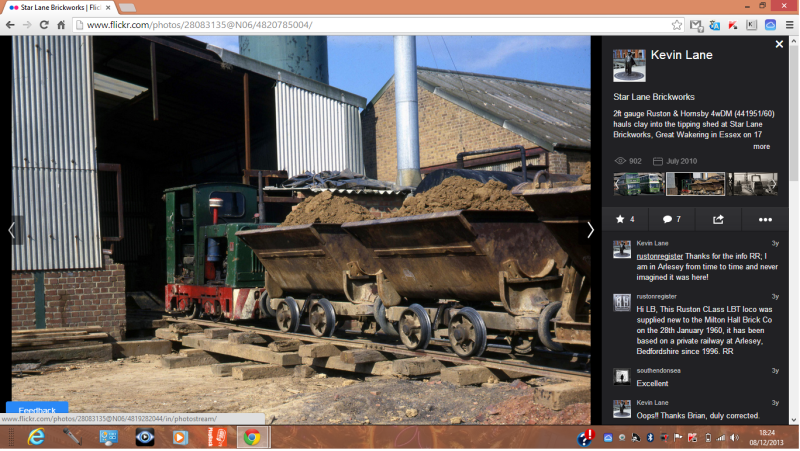

but also railways of various gauges on its site: 2 foot (0.6 m), 3 foot (0.9 m), and standard gauge

(4 ft 8’A in = 1.435 m) systems have been noted on various maps and after the Great War this

profusion is noted in the Quarry Act returns in the 1920s and 1930s (Table 6).

Apart from Beart’s, two other brickmaking firms were operating in Arlesey in 1858,

As with Beart’s later competitors, mentioned above, each produced a buff/off-white Gault brick. One firm operating

in the 1860s had stopped production by the time surveying was undertaken for an Ordnance

Survey in 1880-81, where ‘old brickworks’ designate the site of the works of the Great Northern

Brick Company, the successor in business to William Dennis’ brickworks noted in 1858.

Concerning the Arlsey Brick Company noted by Robert Hunt in 1858, it is not possible

to add to the basic information given in Table 5; as the Arlesey Brick and Lime Company it may

be a predecessor of the Arlesey Brick, Lime and Cement Company mentioned above.

below figures for Bearts Arlesey

The Arlesey Gault bricks don’t cut well unlike the 1930 Arlesey Whites that do.It must be to do with the better method of drying and firing.The gault bricks have no frogs or flutes either , just all flat faces. I don’t know where the gault bricks came from cos my house is 1930’s and the gault bricks were a lot earlier than that.Even earlier than the Arlesey whites with all the holes in them

My brick collection of just one brick…

LikeLike

SERIAL : BB364 ** Please quote this in all correspondence **

DATE : 19-Dec-1943

UNIT : 138 Sqdn

AIRCRAFT : Handley Page Halifax II

RAF BASE : Tempsford, GPS location 52.159479 / -0.26843

SQUADRON or UNIT CODES : NF:R

TARGET : Training

CAUSE OF LOSS : Crashed / general

– – – – – – – – – – – – – – – – – – – – – – – – –

Pilot : Sergeant Hubert Gwyn Williams RAFVR 1394323 [Killed] 19 December 1943. Taliaris (Holy Trinity) Churchyard, United Kingdom Sw Part. Son of Joseph and Sarah Williams of Manordilo. CWGC Casualty link : https://www.cwgc.org/find-war-dead/casualty/2965486

Flight Engineer : Sergeant Stanley Higham RAFVR 1523110 [Killed] 19 December 1943. Mawdesley (St. Peter) Churchyard, United Kingdom Grave 35. Son of James and Margaret Higham of Mawdesley. CWGC Casualty link : https://www.cwgc.org/find-war-dead/casualty/2403829

Navigator : Sergeant Harold Maitland Houghton RAFVR 1543667 [Killed] 19 December 1943. Horwich (Ridgmont) Cemetery, United Kingdom Div 2 Sec 2. Son of Ernest and Annie Houghton of Horwich. CWGC Casualty link : https://www.cwgc.org/find-war-dead/casualty/2699031

Navigator : Sergeant Joseph Norman Polland RAFVR 1485923 [Killed] 19 December 1943. Belfast (Dundonald) Cemetery, United Kingdom Sec E2 Grave. Son of Samuel and Sara Polland of Belfast. CWGC Casualty link : https://www.cwgc.org/find-war-dead/casualty/2690194

Navigator : Pilot Officer Cyril Arthur Woolldridge RAFVR 155858 (NCO:1257554) [Killed] 19 December 1943. Brookwood Military Cemetery, United Kingdom 21 C 19. Son of Laurence Cyril and Marie Elizabeth Woolldridge. Husband of Lena Marguerite Woolldridge of Bromley Kent. CWGC Casualty link : https://www.cwgc.org/find-war-dead/casualty/2929512 : Gazetted Commission Date : 05 October 1943

Wireless Operator / Air Gunner : Sergeant Frank Henry Adams RAFVR 1395215 [Killed] 19 December 1943. Islington Cemetery And Crematorium, United Kingdom Sec O Block 9. Son of Frank Henry and Violet Elizabeth Adams. Husband of Elizabeth May Adams of Islington London. CWGC Casualty link : https://www.cwgc.org/find-war-dead/casualty/2735085

Air Gunner : Sergeant Cyril Addison Kidd RAFVR 2210121 [Killed] 19 December 1943. Liverpool (Kirkdale) Cemetery, United Kingdom Sec 20 C Of. Son of Frederick Robert and May Kidd. Husband of Jane Elizabeth Kidd of Liverpool. CWGC Casualty link : https://www.cwgc.org/find-war-dead/casualty/2412304

Air Gunner : Sergeant John Edward Mooney RAFVR 1032093 [Killed] 19 December 1943. Liverpool (Ford) Roman Catholic Cemetery, United Kingdom Sec Ae Grave. Son of William and Johanna Mooney of Liverpool. Husband of Robina Josephine Mooney of Kensington Liverpool. CWGC Casualty link : https://www.cwgc.org/find-war-dead/casualty/2412182

(If 2 military service numbers are shown, the 1st is that held at the time of the incident. The 2nd one is for a previous / subsequent rank; an NCO later an Officer, or an Officer previously an NCO.)

“Gazetted Commission Date” is when the London Gazette published the Commission, and this frequently postdates the date of seniority.

– – – – – – – – – – – – – – – – – – – – – – – – –

These are the Commonwealth War Graves Cemetery details for this loss record:-

Belfast (Dundonald) Cemetery, United Kingdom’s GPS Location is 54.594163 / -5.820670, which has 42 casualties.

Brookwood Military Cemetery, United Kingdom’s GPS Location is 51.300276 / -0.640910, which has 1,356 casualties.

Horwich (Ridgmont) Cemetery, United Kingdom’s GPS Location is 53.598439 / -2.530900, which has 4 casualties.

Islington Cemetery And Crematorium, United Kingdom’s GPS Location is 51.597882 / -0.167796, which has 73 casualties.

Liverpool (Ford) Roman Catholic Cemetery, United Kingdom’s GPS Location is 53.480705 / -2.992926, which has 24 casualties.

Liverpool (Kirkdale) Cemetery, United Kingdom’s GPS Location is 53.469177 / -2.948197, which has 30 casualties.

Mawdesley (St. Peter) Churchyard, United Kingdom, which has 1 casualties.

Taliaris (Holy Trinity) Churchyard, United Kingdom, which has 1 casualties.

You can use mapping software such as Google Earth (and its Street View) to look at these locations.

– – – – – – – – – – – – – – – – – – – – – – – – –

DETAILS : Crashed after colliding with a tall factory chimney on the site of Arlesey brickworks, 1 mile south-east of Henlow, Bedfordshire (GPS 52.029638 / -0.264186). Both air gunners came from Liverpool; Sgt Mooney buried Ford Roman Catholic Cemetery; Sgt Kidd, Kirkdale Cemetery. The accident happened during container dropping practice over Henlow aerodrome.

– – – – – – – – – – – – – – – – – – – – – – – – –

The database has only one publication reference for this aircraft loss:-

Personal Files. Author : Davis, Rob.

In the BB364 folder, an historical photo of the factory and tall chimneys before demolition

The database has no related or associated losses.

The database has no service summary for this aircraft.

– – – – – – – – – – – – – – – – – – – – – – – – –

Websites:-

Bomber Command : http://robdavistelford.co.uk/webspace/raf_bc/index.html

Finding/rearching aircrew : http://robdavistelford.co.uk/webspace/raf_bc/finding.html

The Great Escape : http://robdavistelford.co.uk/webspace/gt_esc/index.html

Commonwealth War Graves Commission online database : http://www.cwgc.org

– – – – – – – – – – – – – – – – – – – – – – – – –

Rob Davis Bomber Command Losses Database. Friday, December 11, 2020.

=================================================

LikeLike

I can identify the public house shown in the photo of the footbridge at Three Counties Station as The Brickground Hotel. It stood next to The Cosy Cinema. A short distance away was The Lamb Inn and The True Briton. (There were 13 pubs in Arlesey). I remember the Sports Ground and Bowliing Green set up by the London Brick Company & Fordhams for their workers. My uncle, Ralph Kitely, was the groundsman for some time. LBC used the trade-name ‘PHORPRES (Four press) for some of their bricks.’

LikeLiked by 1 person